Standardized molded-in threaded inserts for plastic, rubber, and ceramics. These high-quality inserts are Made in the USA and engineered to provide reliable performance in a range of different applications. Patented design. Prototype to production. FREE samples available!

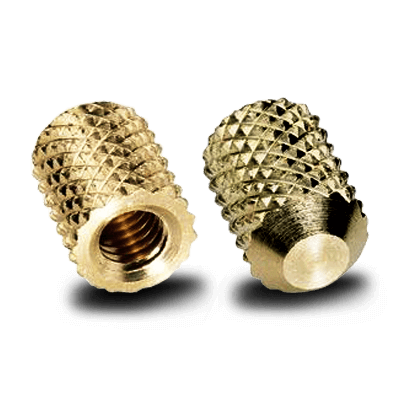

TYPE A Molded-In Inserts feature patented designs for molded-in use. Close tolerance of minor thread diameter and careful burnishing of inner thread crests assure snug fit on pins. Extremely flat ends on inserts (with no burrs, ridges or other defects) mean no leakage of material on the face of the mold.

TYPE B Molded-In Inserts feature patented designs for molded-in use. Close tolerance of minor thread diameter and careful burnishing of inner thread crests assure snug fit on pins. Extremely flat ends on inserts (with no burrs, ridges or other defects) mean no leakage of material on the face of the mold.

TYPE C Molded-In Inserts feature patented designs for molded-in use. Close tolerance of minor thread diameter and careful burnishing of inner thread crests assure snug fit on pins. Extremely flat ends on inserts (with no burrs, ridges or other defects) mean no leakage of material on the face of the mold.

TYPE D Studded Molded-In Inserts feature patented designs for molded-in use. Proportioned for maximum holding strength. Can be screwed to butt flush with a Yardley Type C Insert.

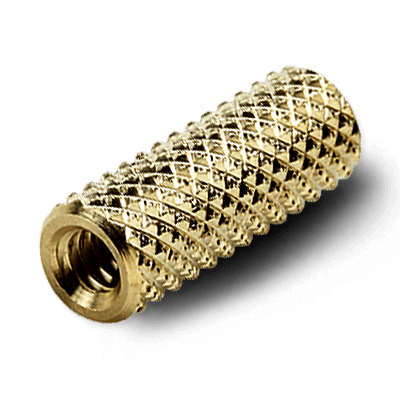

TYPE AA Molded-In Inserts feature a new design for molded-in use. Close tolerance of minor thread diameter and careful burnishing of inner thread crests assure snug fit on locating pins. Smooth ring on open end of insert eliminates knurl teeth showing on surface of molded part.

TYPE BB Molded-In Inserts feature a new design for molded-in use. Close tolerance of minor thread diameter and careful burnishing of inner thread crests assure snug fit on locating pins. Both ends of insert are chamfered to eliminate knurl teeth showing on surface of molded part.