Shop our full catalog of threaded metal inserts and inserting tools, from molded-in and pressed-in inserts to the thermal inserting press.

A simple, inexpensive method for installing metal inserts permanently in thermoplastic. Ideal for prototype and low volume production. Permits accurate control of temperature to prevent damage to plastic. Provides a strong, permanent installation of inserts with high resistance to rotation and pull-out.

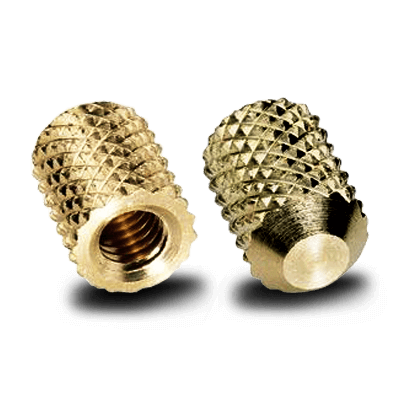

A wide range of threaded inserts featuring patented designs for molded-in use. Close tolerance of minor thread diameter and careful burnishing of inner thread crests assure snug fit on pins. Extremely flat ends on inserts (with no burrs, ridges or other defects) mean no leakage of material on the face of the mold. Available in Brass, Aluminum and Stainless Steel.

Threaded stud inserts featuring patented designs for molded-in use. Proportioned for maximum holding strength. Can be screwed to butt flush with a Yardley Type C Insert. Available in Brass.

Spiral knurled, open or closed-ended inserts for pressing into soft materials such as plastics, foamed plastics and rubber. Ideal for use where minimal pull-out strength is needed, but some torque resistance is required. Can also be molded-in and feature patented I.D. design for use with locating pins. Available in Brass and Aluminum.

Specifically designed for the Rotational Molding process, this versatile insert provides exceptional torque and pull-out resistance. Unique Hex design allows the Bi-Sert to be used with fibrous materials where the fibers would normally block the flow of the plastic material around ordinary diamond knurled inserts. Inside diameter held to strict tolerances for a smooth, tight fit on locating pins. Available in Brass.

Special design makes them ideal for wood, particle board, ABS and foamed plastics. Large coarse outer threads give great holding power in weaker materials while inside threads stay clean, free of chips. Install with Yardley pneumatic inserter or easy-to-use self-tapping driver. Available in Brass and Diecast.

For use in thermoplastic materials such as ABS and polycarbonates. Intro-Serts have no sharp edges on their outer annular ribs to cause residual stress cracking. Install them fast and easily with ultrasonic or thermal insertion tools. Available in Brass, Aluminum and Stainless Steel.

Designed for fast easy press-in installation, providing permanent threads in aluminum, soft metals and plastics. The knurled body locks tightly in the host material and its thick wall design prevents thread distortion. It also can be swaged to metal tubing. Available in Plated Steel.

Designed for fast easy press-in installation, providing permanent threads in aluminum and other soft metals. Its smooth tapered lead allows easy positioning for quick starts in a pre-drilled hole and the knurled body locks tightly in the host material. Its thick wall design prevents thread distortion. Available in Plated Steel.

Versatile, economical and trouble free, they offer easy, high-speed installation. Curved hooks and lateral flutes lock them into plastics, particle board and wood. Install with ultrasonic or thermal tools or just hammer or press them in. Available in Brass.

For strong threads in plastics, soft metals and wood. Self-tapping, they provide high torque and pull-out resistance. Install with Yardley pneumatic inserter or insert driver. Available in Brass, Plated Steel and Stainless Steel (Coarse Series in Brass Only).

Economical design features a lead on both ends making this insert ideal for high volume, automated production. Unique radial barbs provide strong resistance to pull-out and rotation in plastics and thermoplastics. Can be molded-in or installed with ultrasonic or thermal insertion tools. Available in Brass.